Optimal Design of Multilayered Building Insulation#

Thermal insulation is installed in buildings to reduce annual energy costs. However, the installation costs money, so the decision of how much insulation to install is a trade-off between the annualized capital costs of insulation and the annual operating costs for heating and air conditioning. This notebook shows the formulation and solution of an optimization problem using conic optimization.

# install dependencies and select solver

%pip install -q amplpy numpy pandas

SOLVER_CONIC = "mosek" # ipopt, mosek, gurobi, knitro

from amplpy import AMPL, ampl_notebook

ampl = ampl_notebook(

modules=["coin", "mosek"], # modules to install

license_uuid="default", # license to use

) # instantiate AMPL object and register notebook magics

from IPython.display import Markdown, HTML

import numpy as np

import matplotlib.pyplot as plt

Please provide a valid license UUID. You can use a free https://ampl.com/ce license.

A Model for Multi-Layered Insulation#

Consider a wall or surface separating conditioned interior space in a building at temperature \(T_i\) from the external environment at temperature \(T_o\). Heat conduction through the wall is given by

where \(U\) is the overall heat transfer coefficient and and \(A\) is the heat transfer area. For a wall constructed from \(N\) layers of different insulating materials, the inverse of the overall heat transfer coefficient \(U\) is given by a sum of serial thermal “resistances”

where \(R_0\) is the thermal resistance of the structural elements. The thermal resistance of the \(n\)-th insulating layer is equal to \(R_n = \frac{x_n}{k_n}\) for a material with thickness \(x_n\) and a thermal conductivity \(k_n\), so we can rewrite

The economic objective is to minimize the cost \(C\), obtained as the combined annual energy operating expenses and capital cost of insulation.

We assume the annual energy costs are proportional to overall heat transfer coefficient \(U\) and let \(\alpha \geq 0\) be the coefficient for the proportional relationship of the overall heat transfer coefficient \(U\) to the annual energy costs. Furthermore, we assume the cost of installing a unit area of insulation in the \(n\)-th layer is given by the affine expression \(a_n + b_n x_n\). The combined annualized costs are then

where \(\beta\) is a discount factor for the equivalent annualized cost of insulation, and \(y_n\) is a binary variable that indicates whether or not layer \(n\) is included in the installation. The feasible values for \(x_n\) are subject to constraints

where \(T\) is an upper bound on insulation thickness.

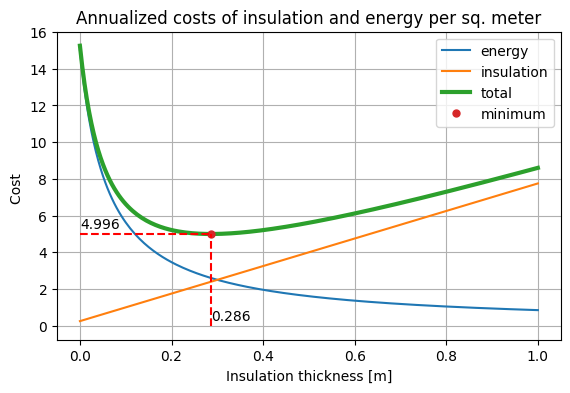

Analytic solution for \(N=1\)#

In the case of a single layer, i.e., \(N=1\), we have a one-dimensional cost optimization problem of which we can obtain a close-form analytical solution directly. Indeed, the expression for the cost \(C(x)\) as a function of the thickness \(x\) reads

For fixed parameters \(k\), \(R_0\), \(\beta\), \(b\), we can calculate the optimum thickness \(x^*\) as

A plot illustrates the trade-off between energy operating costs and capital insulation costs and the corresponding optimal solution \(x^*\).

# application parameters

alpha = 30 # $ K / W annualized cost per sq meter per W/sq m/K

beta = 0.05 # equivalent annual cost factor

R0 = 2.0 # Watts/K/m**2

T = 0.30 # maximum insulation thickness

# material properties

k = 0.030 # thermal conductivity as installed

a = 5.0 # installation cost per square meter

b = 150.0 # installed material cost per cubic meter

import matplotlib.pyplot as plt

import numpy as np

f = lambda x: alpha / (R0 + x / k)

g = lambda x: beta * (a + b * x)

# solution

xopt = -k * R0 + np.sqrt(alpha * k / beta / b)

print(f"The optimal cost is equal to {f(xopt) + g(xopt):0.5f} per sq. meter")

print(f"The optimal thickness is {xopt:0.5f} meters\n")

# plotting

x = np.linspace(0, 1, 201)

fig, ax = plt.subplots(1, 1, figsize=(6.5, 4))

ax.plot(x, f(x), label="energy")

ax.plot(x, g(x), label="insulation")

ax.plot(x, f(x) + g(x), label="total", lw=3)

ax.plot(xopt, f(xopt) + g(xopt), ".", ms=10, label="minimum")

ax.legend()

ax.plot([0, xopt], [f(xopt) + g(xopt)] * 2, "r--")

ax.plot([xopt] * 2, [0, f(xopt) + g(xopt)], "r--")

ax.text(0, f(xopt) + g(xopt) + 0.3, f"{f(xopt) + g(xopt):0.3f}")

ax.text(xopt, 0.3, f"{xopt:0.3f}")

ax.set_xlabel("Insulation thickness [m]")

ax.set_ylabel("Cost ")

ax.set_title("Annualized costs of insulation and energy per sq. meter")

ax.grid(True)

The optimal cost is equal to 4.99615 per sq. meter

The optimal thickness is 0.28641 meters

AMPL Model for \(N=1\)#

A conic rotated constraint in AMPL can be represented as follows:

where \(r_1, r_2\), and \(z_0, z_1, \ldots, z_{N-1}\) are variables. For a single layer AMPL model we identify \(R \sim r_1\), \(U\sim r_2\), and \(z_0^2 \sim 2\) which leads to the model

ampl = AMPL()

ampl.eval(

r"""

# application parameters

param alpha; # $ K / W annualized cost per sq meter per W/sq m/K

param beta; # equivalent annual cost factor

param R0; # Watts/K/m**2

param T; # maximum insulation thickness

# material properties

param k; # thermal conductivity as installed

param a; # installation cost per square meter

param b; # installed material cost per cubic meter

# decision variables

var R >= 0;

var U >= 0;

var x >= 0 <= T;

# objective

minimize cost: alpha*U + beta*(a + b*x);

# insulation model

s.t. r: R == R0 + x/k;

# conic constraint

s.t. q: R*U >= 1;

"""

)

ampl.param["alpha"] = alpha

ampl.param["beta"] = beta

ampl.param["R0"] = R0

ampl.param["T"] = T

ampl.param["k"] = k

ampl.param["a"] = a

ampl.param["b"] = b

ampl.option["solver"] = SOLVER_CONIC

ampl.solve()

print(

f"The optimal cost is equal to {ampl.get_objective('cost').value():0.5f} per sq. meter"

)

print(f"The optimal thickness is xopt = {ampl.get_value('x'):0.5f} meters")

MOSEK 10.0.43: MOSEK 10.0.43: optimal; objective 4.996152429

0 simplex iterations

11 barrier iterations

The optimal cost is equal to 4.99615 per sq. meter

The optimal thickness is xopt = 0.28642 meters

Multi-Layer Solutions as a Mixed Integer Quadratic Constraint Optimization (MIQCO)#

For multiple layers, we cannot easily find an analytical optimal layer composition and we shall resort to conic optimization. Let \(y_n\) be the binary variable that indicates whether layer \(n\) is included in the insulation package or not, and \(x_n\) be the continuous variable describing the thickness of layer \(n\), which is zero if layer \(n\) is not included.

In the general case with \(N\) layers, the objective function is given by

where the first term is nonlinear in the variables \(x_1,\dots,x_N\) since since the denominator of the first term is equal tosince at the denominator of the first term is equal to

To overcome this issue, we can include \(U\) as a decision variable and include a constraint

Since we minimize the objective and \(U\) has no other constraint, the problem will guarantee that \(U\) is equal to \(1/R\). The extra constraint \(RU \leq 1\) can be reformulated using an extra decision variable \(z\) as:

from which we see that the entire problem can be reformulated as a conic optimization problem.

The middle formulation above can, in fact, be implemented in AMPL as a conic rotated constraint of the form:

In our case, we pick \(n=1\), \(z_0 = z\), \(r_1=R\), and \(r_2=U\).

Adopting this formulation, the full multi-layer optimization problem then reads:

def insulate(df, alpha, beta, R0, T):

ampl = AMPL()

ampl.eval(

r"""

# application parameters

param alpha; # $ K / W annualized cost per sq meter per W/sq m/K

param beta; # equivalent annual cost factor

param R0; # Watts/K/m**2

param T; # maximum insulation thickness

# material properties

set MAT;

param k{MAT}; # thermal conductivity as installed

param a{MAT}; # installation cost per square meter

param b{MAT}; # installed material cost per cubic meter

# decision variables

var R >= 0;

var U >= 0;

var x{MAT} >= 0;

var y{MAT} binary;

# objective

minimize cost:

alpha*U + beta * sum {i in MAT} (a[i] + b[i]*x[i]);

# insulation model

s.t. insulation: R == R0 + sum {i in MAT} x[i]/k[i];

# total thickness limit

s.t. thickness: sum {i in MAT} x[i] <= T;

# layer model

s.t. layers {i in MAT}:

x[i] <= T * y[i];

# conic constraint

s.t. q: R*U >= 1;

"""

)

ampl.param["alpha"] = alpha

ampl.param["beta"] = beta

ampl.param["R0"] = R0

ampl.param["T"] = T

ampl.set["MAT"] = list(df.index)

ampl.set_data(df, "MAT")

ampl.option["solver"] = SOLVER_CONIC

ampl.solve()

df["x_opt"] = ampl.get_variable("x").to_pandas()

print(

f"\nThe optimal cost is equal to"

f" {ampl.get_objective('cost').value():0.5f} per sq. meter"

)

display(df.round(5))

return ampl

Case 1. Single Layer Solution#

import pandas as pd

# application parameters

alpha = 30 # $ K / W annualized cost per sq meter per W/sq m/K

beta = 0.05 # equivalent annual cost factor

R0 = 2.0 # Watts/K/m**2

T = 0.30 # maximum insulation thickness

df = pd.DataFrame(

{

"Mineral Wool": {"k": 0.030, "a": 5.0, "b": 150.0},

"Rigid Foam (high R)": {"k": 0.015, "a": 8.0, "b": 180.0},

"Rigid Foam (low R)": {"k": 0.3, "a": 8.0, "b": 120.0},

}

).T

m = insulate(df, alpha, beta, R0, T)

MOSEK 10.0.43: MOSEK 10.0.43: optimal; objective 4.804922361

0 simplex iterations

1 branching nodes

The optimal cost is equal to 4.80492 per sq. meter

| k | a | b | x_opt | |

|---|---|---|---|---|

| Mineral Wool | 0.030 | 5.0 | 150.0 | 0.00000 |

| Rigid Foam (high R) | 0.015 | 8.0 | 180.0 | 0.19361 |

| Rigid Foam (low R) | 0.300 | 8.0 | 120.0 | 0.00000 |

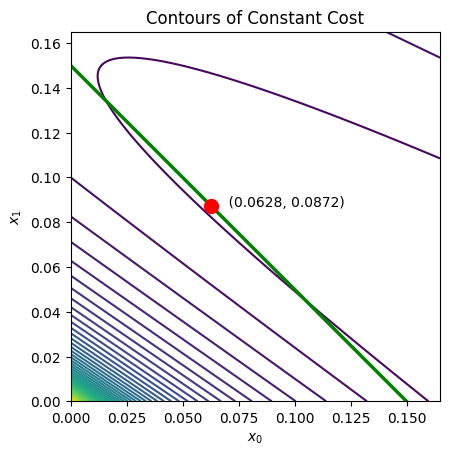

Case 2. Multiple Layer Solution#

# application parameters

alpha = 30 # $ K / W annualized cost per sq meter per W/sq m/K

beta = 0.05 # equivalent annual cost factor

R0 = 2.0 # Watts/K/m**2

T = 0.15 # maximum insulation thickness

df = pd.DataFrame(

{

"Foam": {"k": 0.015, "a": 0.0, "b": 110.0},

"Wool": {"k": 0.010, "a": 0.0, "b": 200.0},

}

).T

m = insulate(df, alpha, beta, R0, T)

MOSEK 10.0.43: MOSEK 10.0.43: optimal; objective 3.229922362

0 simplex iterations

1 branching nodes

The optimal cost is equal to 3.22992 per sq. meter

| k | a | b | x_opt | |

|---|---|---|---|---|

| Foam | 0.015 | 0.0 | 110.0 | 0.06278 |

| Wool | 0.010 | 0.0 | 200.0 | 0.08722 |

The plot below gives a graphical representation of the 2-layer problem we just solved. The green line represents the thickness constraint \(x_0+x_1 \leq T\), the curves are the isolines of the objective function, and the optimal solution \(x^*=(x_0^*,x_1^*)\) is highlighted in red.

import numpy as np

import matplotlib.pyplot as plt

k = list(df["k"])

a = list(df["a"])

b = list(df["b"])

f = lambda x0, x1: alpha / (R0 + x0 / k[0] + x1 / k[1]) + beta * (

a[0] + b[0] * x0 + a[1] + b[1] * x1

)

x0 = np.linspace(0, 1.1 * T, 201)

x1 = np.linspace(0, 1.1 * T, 201)

X0, X1 = np.meshgrid(x0, x1)

fig, ax = plt.subplots(1, 1)

ax.contour(x0, x1, f(X0, X1), 50)

ax.set_xlim(min(x0), max(x0))

ax.set_ylim(min(x1), max(x1))

ax.plot([0, T], [T, 0], "g", lw=2.5)

ax.set_aspect(1)

x = df["x_opt"].to_list()

ax.plot(x[0], x[1], "r.", ms=20)

ax.text(x[0], x[1], f" ({x[0]:0.4f}, {x[1]:0.4f})")

ax.set_xlabel(r"$x_0$")

ax.set_ylabel(r"$x_1$")

ax.set_title("Contours of Constant Cost")

plt.show()

Bibliographic Notes#

To the best of my knowledge, this problem is not well-known example in the mathematical optimization literature. There are a number of application papers with differing levels of detail.

Hasan, A. (1999). Optimizing insulation thickness for buildings using life cycle cost. Applied energy, 63(2), 115-124. https://www.sciencedirect.com/science/article/pii/S0306261999000239

Kaynakli, O. (2012). A review of the economical and optimum thermal insulation thickness for building applications. Renewable and Sustainable Energy Reviews, 16(1), 415-425. https://www.sciencedirect.com/science/article/pii/S1364032111004163

Nyers, J., Kajtar, L., Tomić, S., & Nyers, A. (2015). Investment-savings method for energy-economic optimization of external wall thermal insulation thickness. Energy and Buildings, 86, 268-274. https://www.sciencedirect.com/science/article/pii/S0378778814008688

More recently some modeling papers have appeared

Gori, P., Guattari, C., Evangelisti, L., & Asdrubali, F. (2016). Design criteria for improving insulation effectiveness of multilayer walls. International Journal of Heat and Mass Transfer, 103, 349-359. https://www.sciencedirect.com/science/article/abs/pii/S0017931016303647

Huang, H., Zhou, Y., Huang, R., Wu, H., Sun, Y., Huang, G., & Xu, T. (2020). Optimum insulation thicknesses and energy conservation of building thermal insulation materials in Chinese zone of humid subtropical climate. Sustainable Cities and Society, 52, 101840. https://www.sciencedirect.com/science/article/pii/S221067071931457X

Söylemez, M. S., & Ünsal, M. (1999). Optimum insulation thickness for refrigeration applications. Energy Conversion and Management, 40(1), 13-21. https://www.sciencedirect.com/science/article/pii/S0196890498001253

Açıkkalp, E., & Kandemir, S. Y. (2019). A method for determining optimum insulation thickness: Combined economic and environmental method. Thermal Science and Engineering Progress, 11, 249-253. https://www.sciencedirect.com/science/article/pii/S2451904918305377

Ylmén, P., Mjörnell, K., Berlin, J., & Arfvidsson, J. (2021). Approach to manage parameter and choice uncertainty in life cycle optimisation of building design: Case study of optimal insulation thickness. Building and Environment, 191, 107544. https://www.sciencedirect.com/science/article/pii/S0360132320309112