BIM production revisited#

# install dependencies and select solver

%pip install -q amplpy

SOLVER = "highs"

from amplpy import AMPL, ampl_notebook

ampl = ampl_notebook(

modules=["highs"], # modules to install

license_uuid="default", # license to use

) # instantiate AMPL object and register magics

Problem description#

We consider BIM raw material planning, but now with more sophisticated pricing and acquisition protocols. There are now three suppliers, each of which can deliver the following materials:

A: silicon, germanium and plastic

B: copper

C: all of the above

For the suppliers, the following conditions apply. Copper should be acquired in multiples of 100 gram, since it is delivered in sheets of 100 gram. Unitary materials such as silicon, germanium and plastic may be acquired in any number, but the price is in batches of 100. Meaning that 30 units of silicon with 10 units of germanium and 50 units of plastic cost as much as 1 unit of silicon but half as much as 30 units of silicon with 30 units of germanium and 50 units of plastic. Furthermore, supplier C sells all materials and offers a discount if purchased together: 100 gram of copper and a batch of unitary material cost just 7. This set price is only applied to pairs, meaning that 100 gram of copper and 2 batches cost 13.

The summary of the prices in € is given in the following table:

Supplier |

Copper per sheet of 100 gram |

Batch of units |

Together |

|---|---|---|---|

A |

- |

5 |

- |

B |

3 |

- |

- |

C |

4 |

6 |

7 |

Next, for stocked products inventory costs are incurred, whose summary is given in the following table:

Copper per 10 gram |

Silicon per unit |

Germanium per unit |

Plastic per unit |

|---|---|---|---|

0.1 |

0.02 |

0.02 |

0.02 |

The holding price of copper is per 10 gram and the copper stocked is rounded up to multiples of 10 grams, meaning that 12 grams pay for 20.

The capacity limitations of the warehouse allow for a maximum of \(10\) kilogram of copper in stock at any moment, but there are no practical limitations to the number of units of unitary products in stock.

Recall that BIM has the following stock at the beginning of the year:

Copper |

Silicon |

Germanium |

Plastic |

|---|---|---|---|

480 |

1000 |

1500 |

1750 |

The company would like to have at least the following stock at the end of the year:

Copper |

Silicon |

Germanium |

Plastic |

|---|---|---|---|

200 |

500 |

500 |

1000 |

The goal is to build an optimization model using the data above and solve it to minimize the acquisition and holding costs of the products while meeting the required quantities for production. The production is made-to-order, meaning that no inventory of chips is kept.

from io import StringIO

import pandas as pd

demand_data = """

chip, Jan, Feb, Mar, Apr, May, Jun, Jul, Aug, Sep, Oct, Nov, Dec

logic, 88, 125, 260, 217, 238, 286, 248, 238, 265, 293, 259, 244

memory, 47, 62, 81, 65, 95, 118, 86, 89, 82, 82, 84, 66

"""

demand_chips = pd.read_csv(StringIO(demand_data), index_col="chip")

display(demand_chips)

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| chip | ||||||||||||

| logic | 88 | 125 | 260 | 217 | 238 | 286 | 248 | 238 | 265 | 293 | 259 | 244 |

| memory | 47 | 62 | 81 | 65 | 95 | 118 | 86 | 89 | 82 | 82 | 84 | 66 |

use = dict()

use["logic"] = {"silicon": 1, "plastic": 1, "copper": 4}

use["memory"] = {"germanium": 1, "plastic": 1, "copper": 2}

use = pd.DataFrame.from_dict(use).fillna(0).astype(int)

display(use)

| logic | memory | |

|---|---|---|

| silicon | 1 | 0 |

| plastic | 1 | 1 |

| copper | 4 | 2 |

| germanium | 0 | 1 |

demand = use.dot(demand_chips)

display(demand)

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| silicon | 88 | 125 | 260 | 217 | 238 | 286 | 248 | 238 | 265 | 293 | 259 | 244 |

| plastic | 135 | 187 | 341 | 282 | 333 | 404 | 334 | 327 | 347 | 375 | 343 | 310 |

| copper | 446 | 624 | 1202 | 998 | 1142 | 1380 | 1164 | 1130 | 1224 | 1336 | 1204 | 1108 |

| germanium | 47 | 62 | 81 | 65 | 95 | 118 | 86 | 89 | 82 | 82 | 84 | 66 |

%%writefile BIMproduction_v1.mod

set periods ordered;

set products;

set supplying_batches;

set supplying_copper;

set unitary_products;

param delta{products, periods}; # demand

param pi{supplying_batches}; # aquisition price

param kappa{supplying_copper}; # price of copper sheet

param beta;

param gamma{products}; # unitary holding costs

param Alpha{products}; # initial stock

param Omega{products}; # desired stock

param copper_bucket_size;

param stock_limit;

param batch_size;

param copper_sheet_mass;

var y{periods, supplying_copper} integer >= 0;

var x{unitary_products, periods, supplying_batches} >= 0;

var ss{products, periods} >= 0;

var uu{products, periods} >= 0;

var bb{periods, supplying_batches} integer >= 0;

var pp{periods} integer >= 0;

var rr{periods} integer >= 0;

s.t. units_in_batches {t in periods, s in supplying_batches}:

sum{p in unitary_products} x[p,t,s] <= batch_size * bb[t,s];

s.t. copper_in_buckets {t in periods}:

ss['copper', t] <= copper_bucket_size * rr[t];

s.t. inventory_capacity {t in periods}:

ss['copper', t] <= stock_limit;

s.t. pairs_in_batches {t in periods}:

pp[t] <= bb[t,'C'];

s.t. pairs_in_sheets {t in periods}:

pp[t] <= y[t,'C'];

s.t. bought {t in periods, p in products}:

(if p == 'copper' then

copper_sheet_mass * sum{s in supplying_copper} y[t,s]

else

sum{s in supplying_batches} x[p,t,s])

== uu[p,t];

var acquisition_cost =

sum{t in periods}(

sum{s in supplying_batches} pi[s] * bb[t,s] +

sum{s in supplying_copper} kappa[s] * y[t,s] -

beta * pp[t]

);

var inventory_cost =

sum{t in periods}(

gamma['copper'] * rr[t] +

sum{p in unitary_products} gamma[p] * ss[p,t]

);

minimize total_cost: acquisition_cost + inventory_cost;

s.t. balance {p in products, t in periods}:

(if t == first(periods) then

Alpha[p]

else

ss[p,prev(t)]) +

uu[p,t] == delta[p,t] + ss[p,t];

s.t. finish {p in products}:

ss[p, last(periods)] >= Omega[p];

Overwriting BIMproduction_v1.mod

def BIMproduction_v1(

demand,

existing,

desired,

stock_limit,

supplying_copper,

supplying_batches,

price_copper_sheet,

price_batch,

discounted_price,

batch_size,

copper_sheet_mass,

copper_bucket_size,

unitary_products,

unitary_holding_costs,

):

m = AMPL()

m.read("BIMproduction_v1.mod")

m.set["periods"] = demand.columns

m.set["products"] = demand.index

m.param["delta"] = demand

m.set["supplying_batches"] = supplying_batches

m.param["pi"] = price_batch

m.set["supplying_copper"] = supplying_copper

m.param["kappa"] = price_copper_sheet

m.param["beta"] = price_batch["C"] + price_copper_sheet["C"] - discounted_price

m.set["unitary_products"] = unitary_products

m.param["gamma"] = unitary_holding_costs

m.param["Alpha"] = existing

m.param["Omega"] = desired

m.param["batch_size"] = batch_size

m.param["copper_bucket_size"] = copper_bucket_size

m.param["stock_limit"] = stock_limit

m.param["copper_sheet_mass"] = copper_sheet_mass

return m

m1 = BIMproduction_v1(

demand=demand,

existing={"silicon": 1000, "germanium": 1500, "plastic": 1750, "copper": 4800},

desired={"silicon": 500, "germanium": 500, "plastic": 1000, "copper": 2000},

stock_limit=10000,

supplying_copper=["B", "C"],

supplying_batches=["A", "C"],

price_copper_sheet={"B": 300, "C": 400},

price_batch={"A": 500, "C": 600},

discounted_price=700,

batch_size=100,

copper_sheet_mass=100,

copper_bucket_size=10,

unitary_products=["silicon", "germanium", "plastic"],

unitary_holding_costs={"copper": 10, "silicon": 2, "germanium": 2, "plastic": 2},

)

m1.option["solver"] = SOLVER

m1.option["highs_options"] = "outlev=1"

m1.solve()

HiGHS 1.5.1: tech:outlev=1

Running HiGHS 1.5.1 [date: 2023-06-22, git hash: 93f1876]

Copyright (c) 2023 HiGHS under MIT licence terms

Presolving model

152 rows, 236 cols, 444 nonzeros

113 rows, 197 cols, 366 nonzeros

96 rows, 156 cols, 285 nonzeros

Solving MIP model with:

96 rows

156 cols (0 binary, 72 integer, 23 implied int., 61 continuous)

285 nonzeros

Nodes | B&B Tree | Objective Bounds | Dynamic Constraints | Work

Proc. InQueue | Leaves Expl. | BestBound BestSol Gap | Cuts InLp Confl. | LpIters Time

0 0 0 0.00% -inf inf inf 0 0 0 0 0.0s

R 0 0 0 0.00% 109104 114244 4.50% 0 0 0 67 0.1s

L 0 0 0 0.00% 109957.085557 110216 0.23% 926 61 0 331 0.9s

2.8% inactive integer columns, restarting

Model after restart has 92 rows, 147 cols (11 bin., 58 int., 21 impl., 57 cont.), and 270 nonzeros

0 0 0 0.00% 109957.143248 110216 0.23% 32 0 0 466 0.9s

0 0 0 0.00% 110065.335725 110216 0.14% 32 15 2 500 0.9s

L 0 0 0 0.00% 110065.431752 110216 0.14% 48 16 2 503 1.0s

13.0% inactive integer columns, restarting

Model after restart has 71 rows, 118 cols (12 bin., 46 int., 7 impl., 53 cont.), and 218 nonzeros

0 0 0 0.00% 110065.431752 110216 0.14% 16 0 0 695 1.0s

0 0 0 0.00% 110065.431752 110216 0.14% 16 15 0 718 1.0s

13.8% inactive integer columns, restarting

Model after restart has 57 rows, 96 cols (3 bin., 42 int., 6 impl., 45 cont.), and 173 nonzeros

0 0 0 0.00% 110091.208095 110216 0.11% 11 0 0 783 1.1s

0 0 0 0.00% 110091.208095 110216 0.11% 11 11 0 796 1.1s

Solving report

Status Optimal

Primal bound 110216

Dual bound 110206.854428

Gap 0.0083% (tolerance: 0.01%)

Solution status feasible

110216 (objective)

0 (bound viol.)

2.30926389122e-14 (int. viol.)

0 (row viol.)

Timing 1.31 (total)

0.00 (presolve)

0.00 (postsolve)

Nodes 11

LP iterations 1510 (total)

453 (strong br.)

347 (separation)

466 (heuristics)

HiGHS 1.5.1: optimal solution; objective 110216

1510 simplex iterations

11 branching nodes

absmipgap=9.14557, relmipgap=8.29786e-05

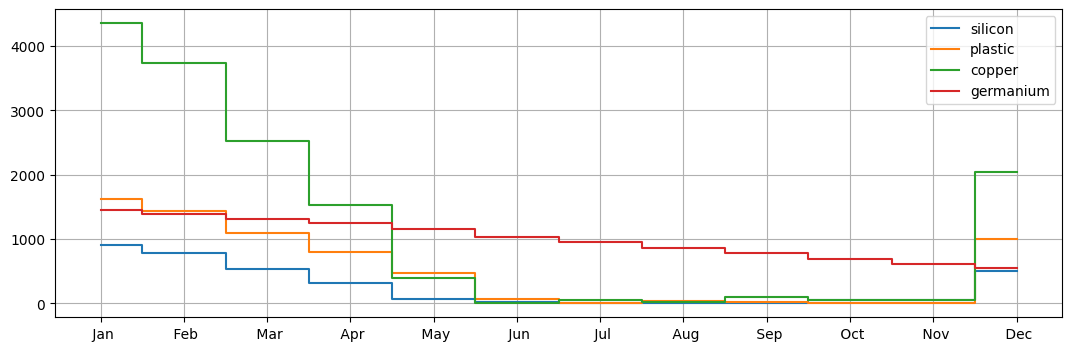

stock = m1.var["ss"].to_pandas().unstack()

stock.columns = stock.columns.get_level_values(1)

stock = stock.reindex(index=demand.index, columns=demand.columns)

display(stock)

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| silicon | 912.0 | 787.0 | 527.0 | 310.0 | 72.0 | 15.0 | 0.0 | 0.0 | 0.0 | 56.0 | 54.0 | 500.0 |

| plastic | 1615.0 | 1428.0 | 1087.0 | 805.0 | 472.0 | 68.0 | 1.0 | 36.0 | 24.0 | 0.0 | 0.0 | 1000.0 |

| copper | 4354.0 | 3730.0 | 2528.0 | 1530.0 | 388.0 | 8.0 | 44.0 | 14.0 | 90.0 | 54.0 | 50.0 | 2042.0 |

| germanium | 1453.0 | 1391.0 | 1310.0 | 1245.0 | 1150.0 | 1032.0 | 946.0 | 857.0 | 775.0 | 693.0 | 609.0 | 543.0 |

import matplotlib.pyplot as plt, numpy as np

stock.T.plot(drawstyle="steps-mid", grid=True, figsize=(13, 4))

plt.xticks(np.arange(len(stock.columns)), stock.columns)

plt.show()

m1.var["pp"].to_pandas().T

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| pp.val | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 3.0 | 5.0 | 6.0 | 6.0 | 7.0 | 6.0 | 20.0 |

df = m1.var["uu"].to_pandas().unstack()

df.columns = df.columns.get_level_values(1)

df = df.reindex(index=demand.index, columns=demand.columns)

display(df)

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| silicon | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 229.0 | 233.0 | 238.0 | 265.0 | 349.0 | 257.0 | 690.0 |

| plastic | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 267.0 | 362.0 | 335.0 | 351.0 | 343.0 | 1310.0 |

| copper | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1000.0 | 1200.0 | 1100.0 | 1300.0 | 1300.0 | 1200.0 | 3100.0 |

| germanium | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

b = m1.var["bb"].to_pandas().unstack().T

b.index = b.index.get_level_values(1)

b = b.reindex(columns=demand.columns)

b.index.names = [None]

display(b)

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| C | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 3.0 | 5.0 | 6.0 | 6.0 | 7.0 | 6.0 | 20.0 |

y = m1.var["y"].to_pandas().unstack().T

y.index = y.index.get_level_values(1)

y = y.reindex(columns=demand.columns)

y.index.names = [None]

display(y)

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 7.0 | 7.0 | 5.0 | 7.0 | 6.0 | 6.0 | 11.0 |

| C | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 3.0 | 5.0 | 6.0 | 6.0 | 7.0 | 6.0 | 20.0 |

x = m1.var["x"].to_pandas().unstack(1)

x.columns = x.columns.get_level_values(1)

x = x.reindex(columns=demand.columns)

x.index.names = ["materials", "supplier"]

display(x)

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| materials | supplier | ||||||||||||

| germanium | A | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| C | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| plastic | A | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| C | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 267.0 | 362.0 | 335.0 | 351.0 | 343.0 | 1310.0 | |

| silicon | A | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| C | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 229.0 | 233.0 | 238.0 | 265.0 | 349.0 | 257.0 | 690.0 |